Products and Services

A list of our broad range of product and services

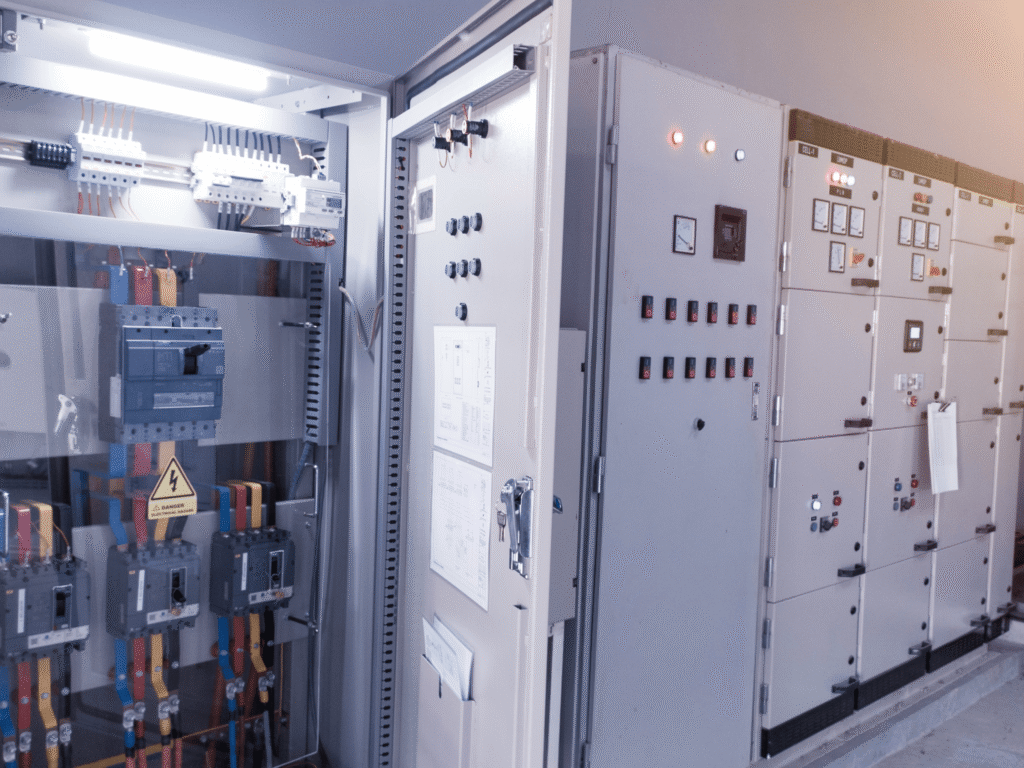

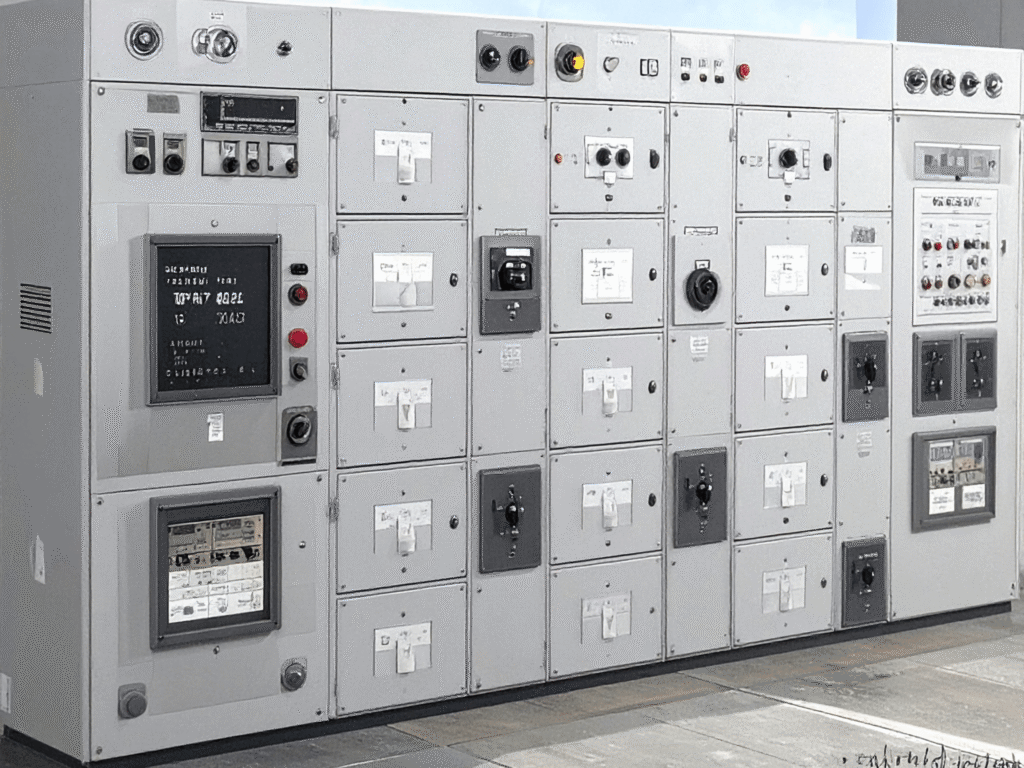

Power Distribution Board

A Power Distribution Board is an electrical panel designed to receive power from a main electrical supply and distribute it safely to multiple outgoing circuits. It houses protective devices such as MCBs, MCCBs, RCCBs, and busbars that control, isolate, and protect electrical loads from overloads, short circuits, and earth faults. Power Distribution Boards help organize electrical systems, improve safety, and ensure reliable power delivery. They are widely used in residential buildings, commercial spaces, industrial plants, and infrastructure projects, making electrical maintenance easier while protecting equipment and ensuring uninterrupted, efficient power distribution.

Lighting Distribution Board

A Lighting Distribution Board is an electrical panel used to distribute electrical power specifically to lighting circuits within a building. It receives power from a main or sub distribution board and supplies it to various lighting points. An LDB contains protective devices like MCBs, RCCBs, switches, and busbars to ensure safe operation. It protects lighting circuits from overloads, short circuits, and earth faults, enables easy control and isolation of lighting systems, and simplifies maintenance. Lighting Distribution Boards are commonly used in residential, commercial, and industrial buildings to ensure efficient, safe, and organized lighting power distribution.

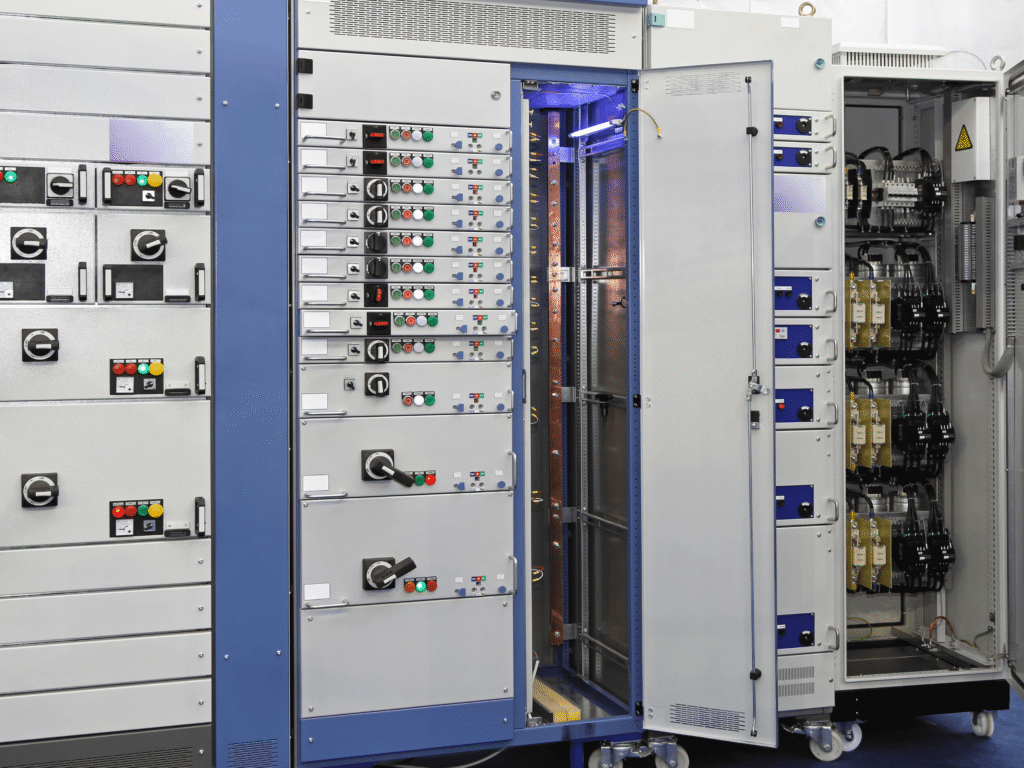

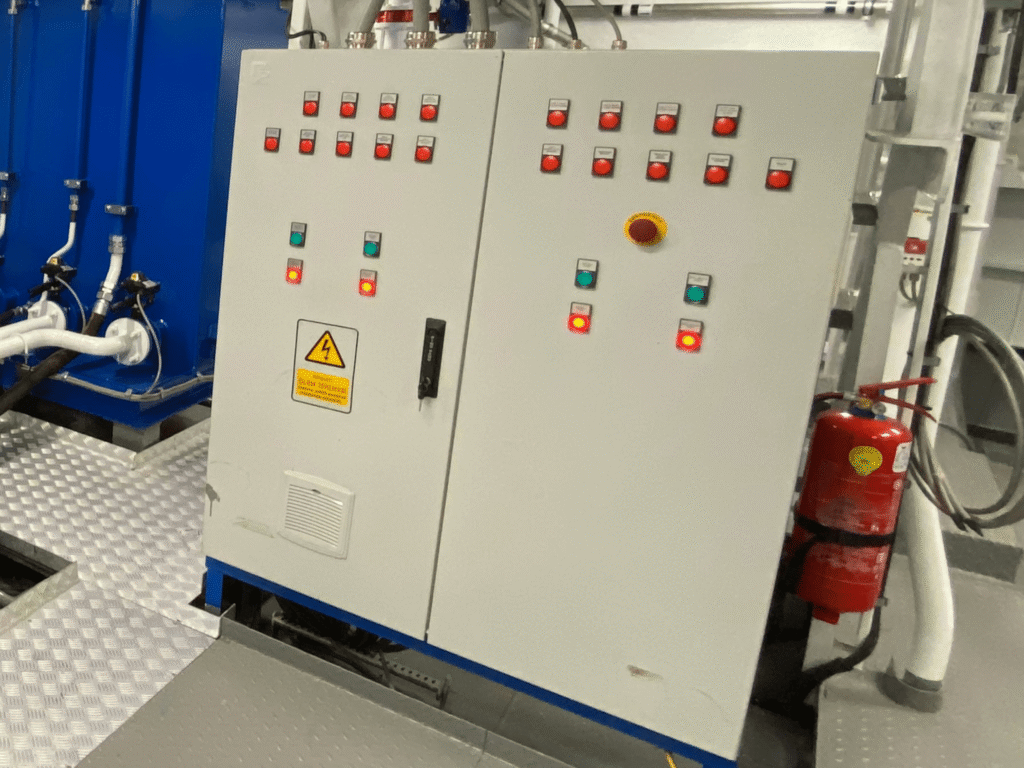

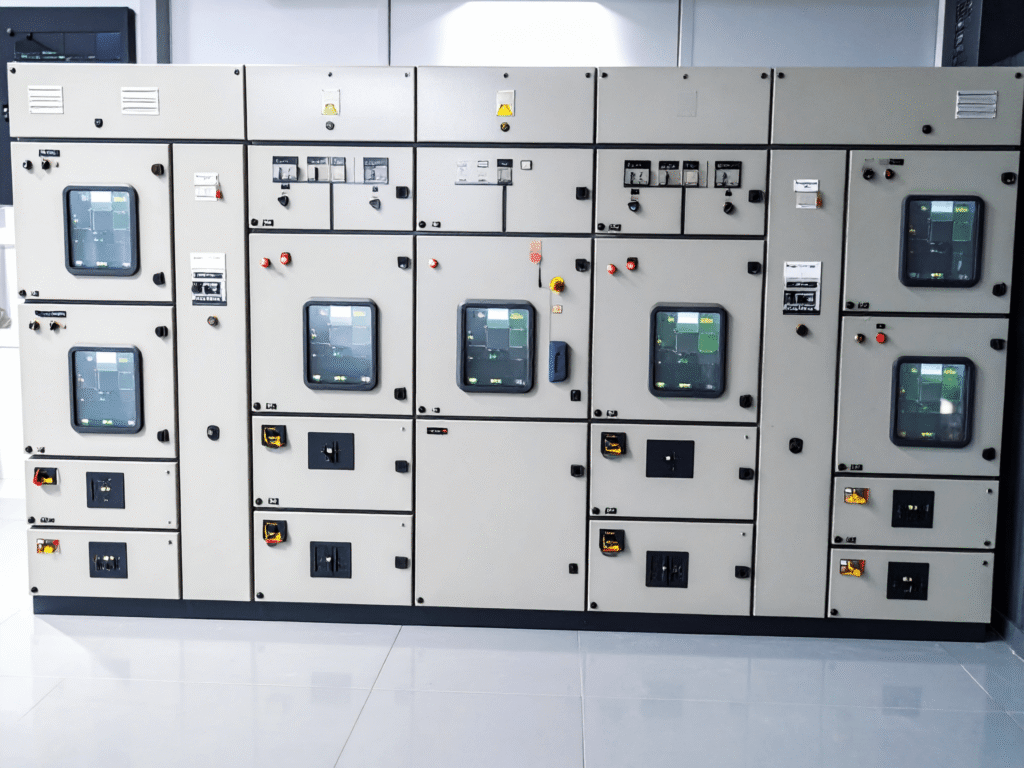

Motor Control Center

A Motor Control Center is a centralized electrical panel used to control, protect, and monitor electric motors in industrial and commercial applications. It houses motor starters, contactors, overload relays, circuit breakers, VFDs, and control devices. An MCC enables safe motor operation by providing protection against overloads, short circuits, and faults, while allowing easy starting, stopping, speed control, and maintenance. Motor Control Centers improve operational efficiency, enhance safety, reduce downtime, and provide organized control of multiple motors from a single location, making them essential for factories, plants, and process industries.

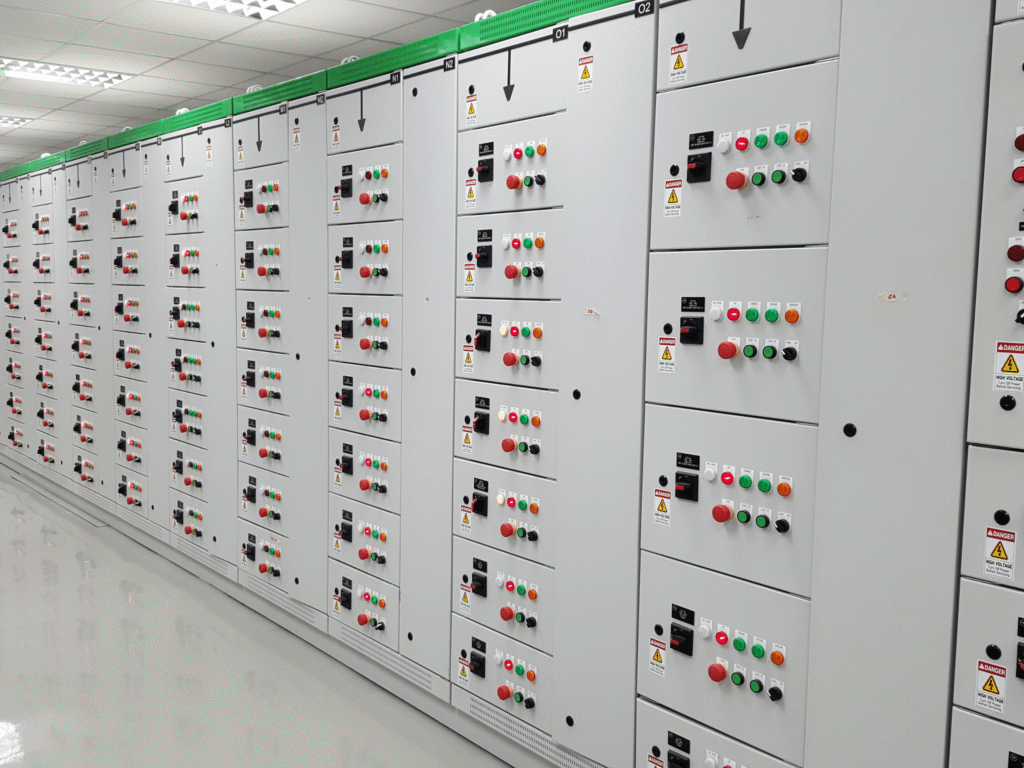

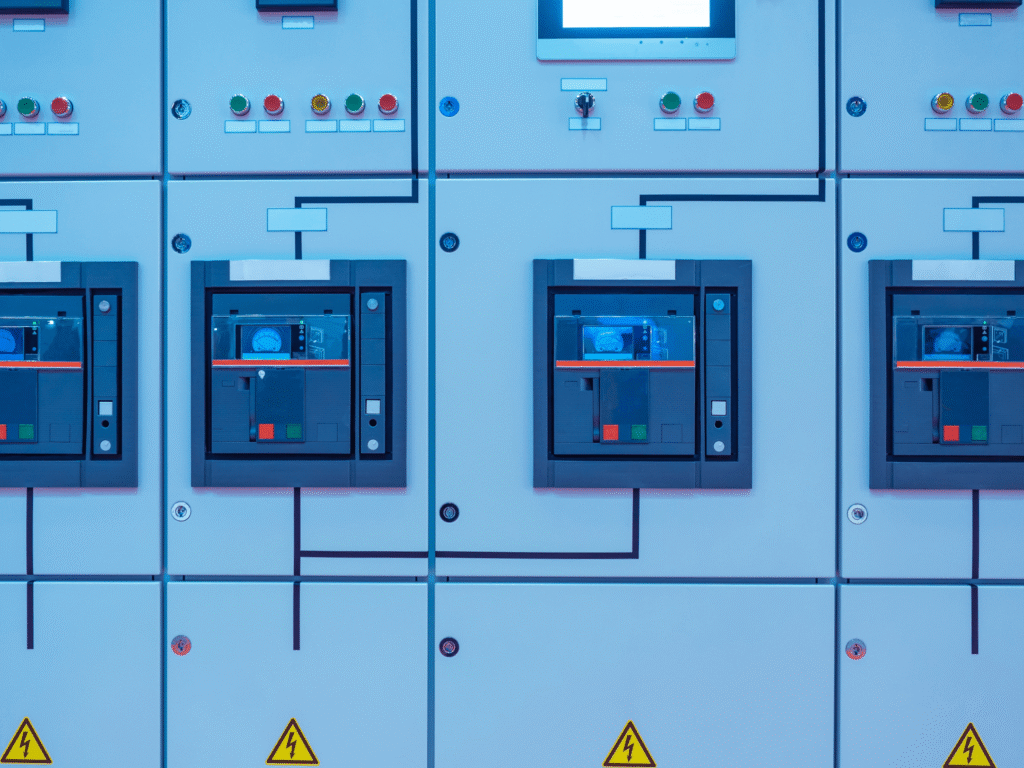

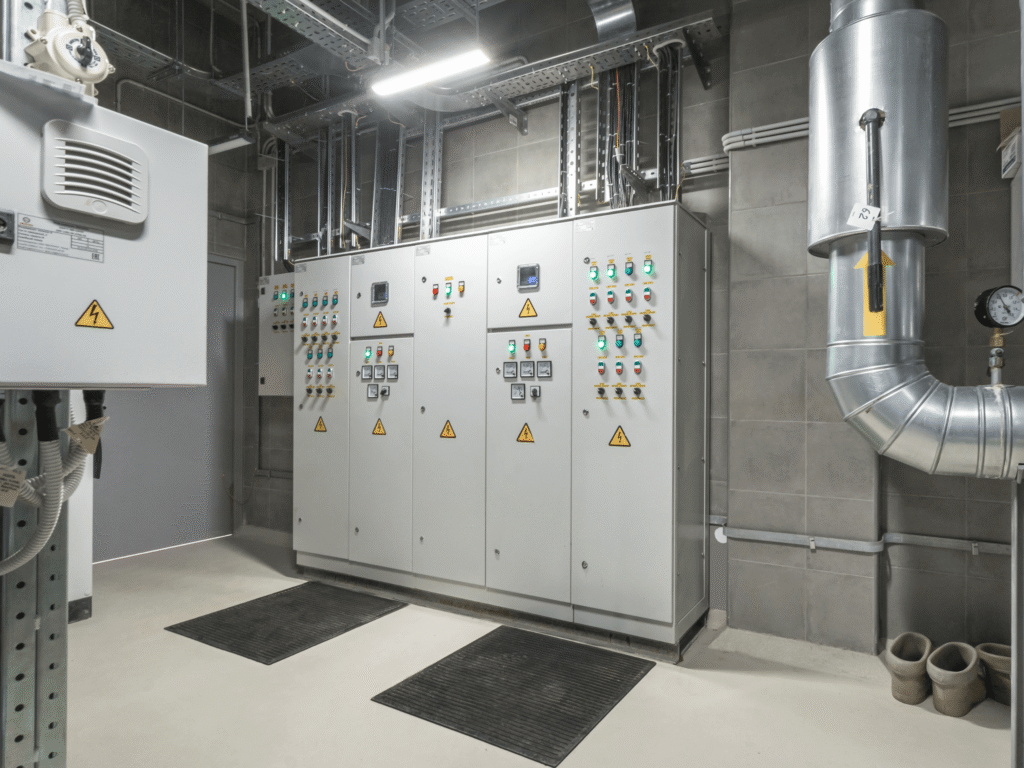

Power Control Center

A Power Control Center (PCC) is a main electrical control panel used to receive power from the utility or generator and distribute it to various downstream panels and loads. It houses devices such as ACBs, MCCBs, busbars, protection relays, and metering systems. A PCC ensures safe, reliable, and efficient power distribution by providing protection against overloads, short circuits, and electrical faults. Commonly used in industrial and large commercial installations, Power Control Centers enable centralized control, monitoring, and isolation of high-capacity electrical systems.

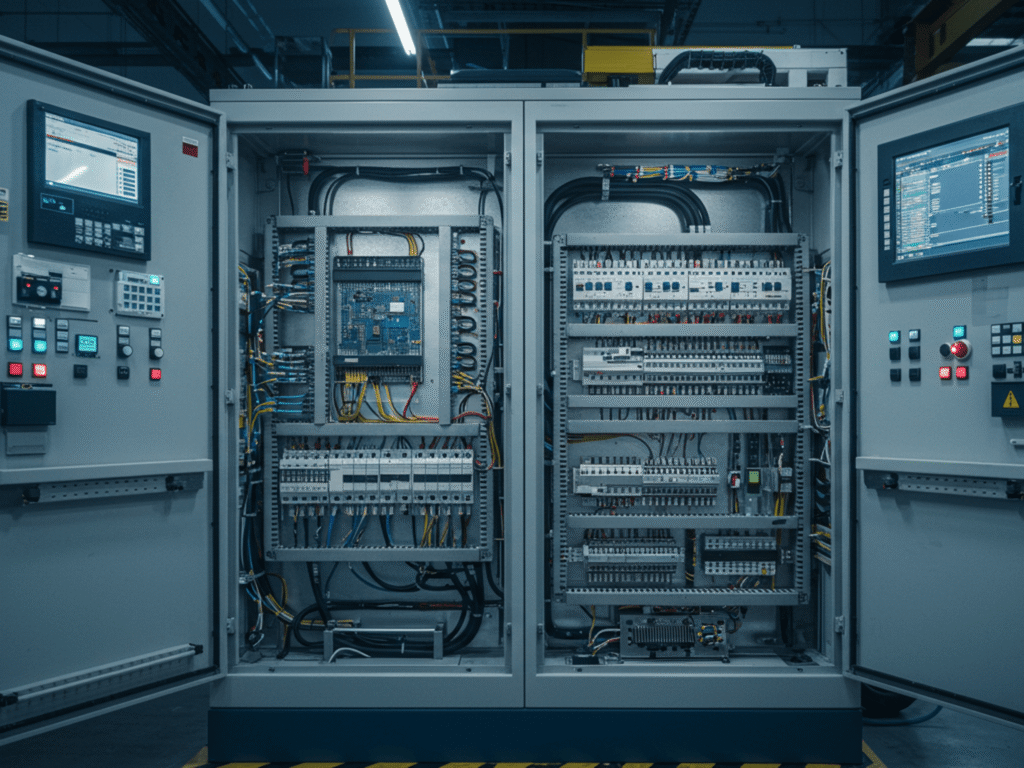

PLC Panel

A PLC Panel (Programmable Logic Controller Panel) is an industrial control panel used to automate and control machines and processes. It contains a PLC, power supply, I/O modules, relays, contactors, and communication devices. The PLC receives input signals from sensors, processes programmed logic, and sends output commands to control equipment. PLC panels improve accuracy, efficiency, and reliability of operations while reducing manual intervention. They are widely used in manufacturing, process industries, utilities, and automation systems for precise control, monitoring, and system integration.

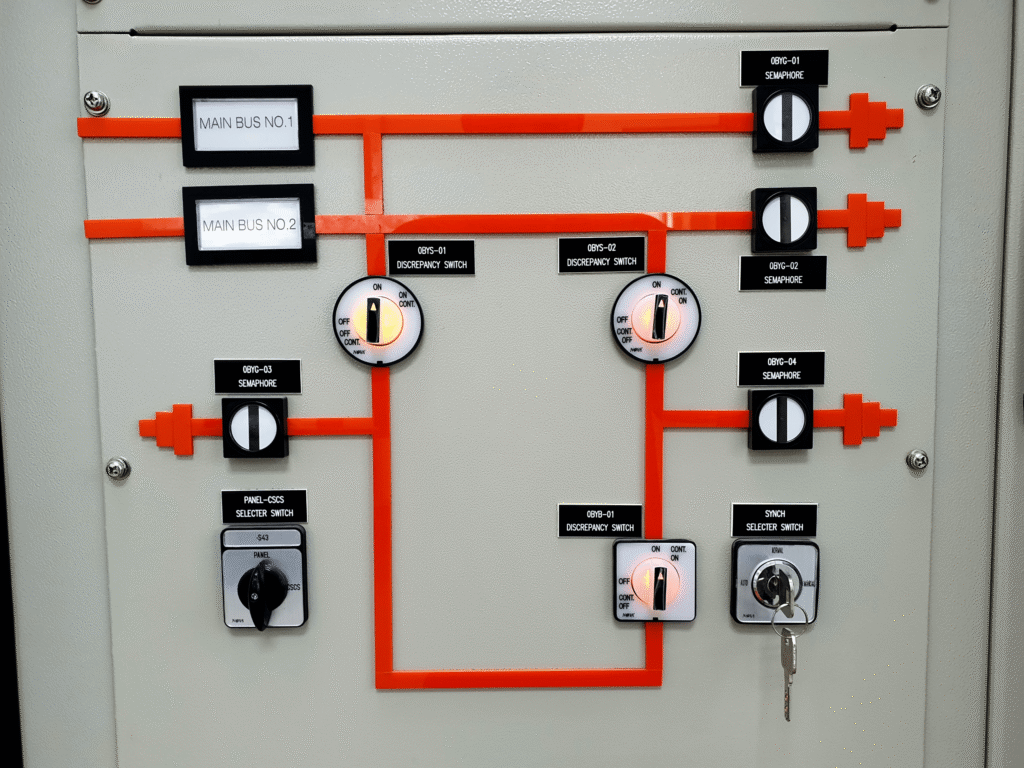

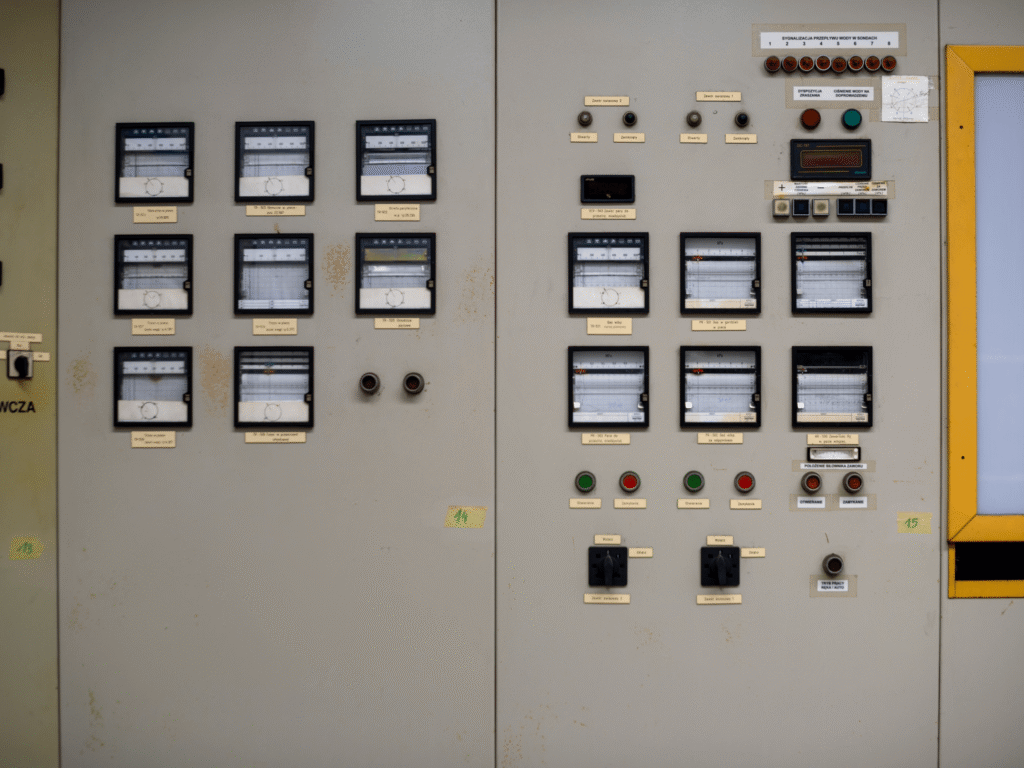

Mimic Panel

A Mimic Panel is a visual control and monitoring panel that represents an electrical or process system using diagrams, symbols, and indicators. It displays real-time status of equipment such as breakers, motors, and switches through lamps, meters, or LEDs. Mimic panels help operators easily understand system layout, monitor operations, quickly identify faults, and take corrective actions. They are commonly used in power plants, substations, industrial facilities, and control rooms to improve operational clarity, safety, and efficient system management.

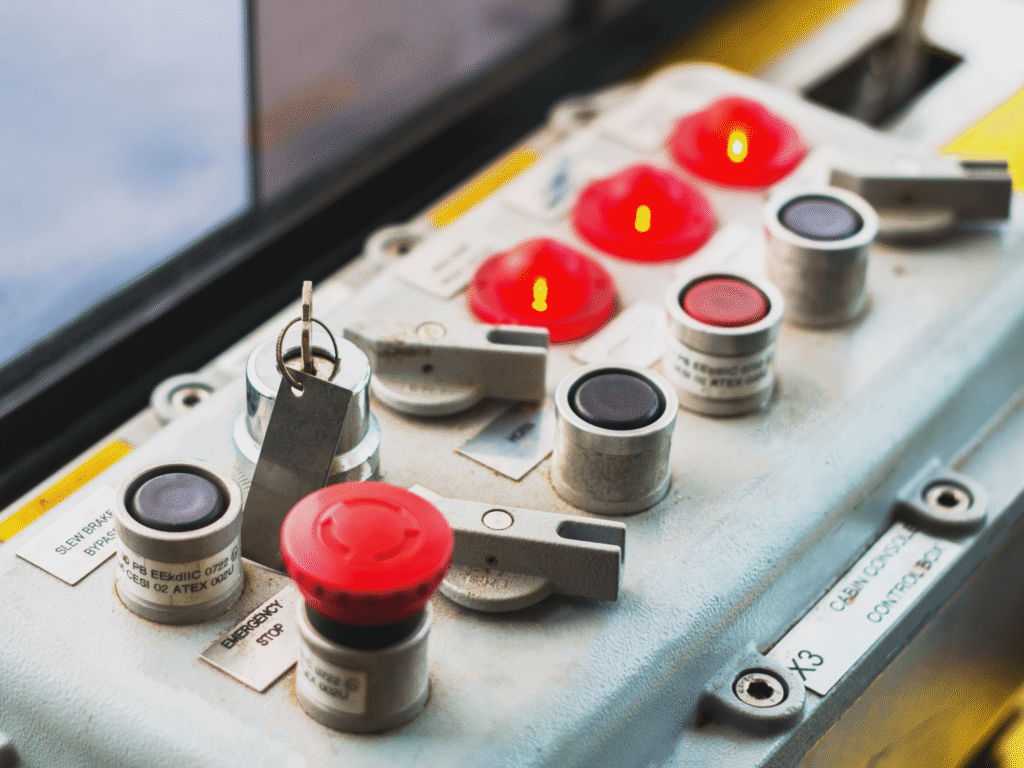

Crane Control Panel

A Crane Control Panel is an electrical control system used to operate and manage crane movements such as hoisting, lowering, traversing, and traveling. It houses components like contactors, relays, VFDs, PLCs, circuit breakers, and safety devices. The panel ensures smooth, precise, and safe crane operation by controlling motor speed, direction, and load handling. It also provides protection against overloads, short circuits, and electrical faults. Crane control panels are widely used in factories, warehouses, ports, and construction sites.

Instrument Panel

An Instrument Panel is a control panel used to display, monitor, and control process parameters such as temperature, pressure, flow, and level. It houses instruments like indicators, transmitters, controllers, recorders, and alarms. Instrument panels provide real-time data, enable accurate process control, and help operators detect abnormalities quickly. They play a crucial role in maintaining safety, efficiency, and quality in industrial processes and are widely used in manufacturing plants, process industries, utilities, and automation systems.

Furnace Control Panel

A Furnace Control Panel is an electrical control system used to operate, monitor, and protect industrial furnaces. It controls functions such as heating, temperature regulation, fuel or power supply, and safety interlocks. The panel houses components like PLCs, temperature controllers, contactors, SCRs, relays, sensors, and protection devices. Furnace control panels ensure precise temperature control, safe operation, energy efficiency, and protection against overheating, electrical faults, and process failures. They are widely used in heat treatment, metallurgy, glass, and manufacturing industries.

Rheostatic Rotor Controller Panel

A Rheostatic Rotor Controller Panel is used to control the starting and speed of slip-ring induction motors. It introduces external resistance into the rotor circuit during startup to limit starting current and increase starting torque. As the motor accelerates, the resistance is gradually reduced. This ensures smooth starting, protects the motor and mechanical system, reduces electrical stress, and improves operational safety. Rheostatic rotor controller panels are commonly used in cranes, hoists, elevators, conveyors, and heavy-duty industrial applications where high starting torque is required.

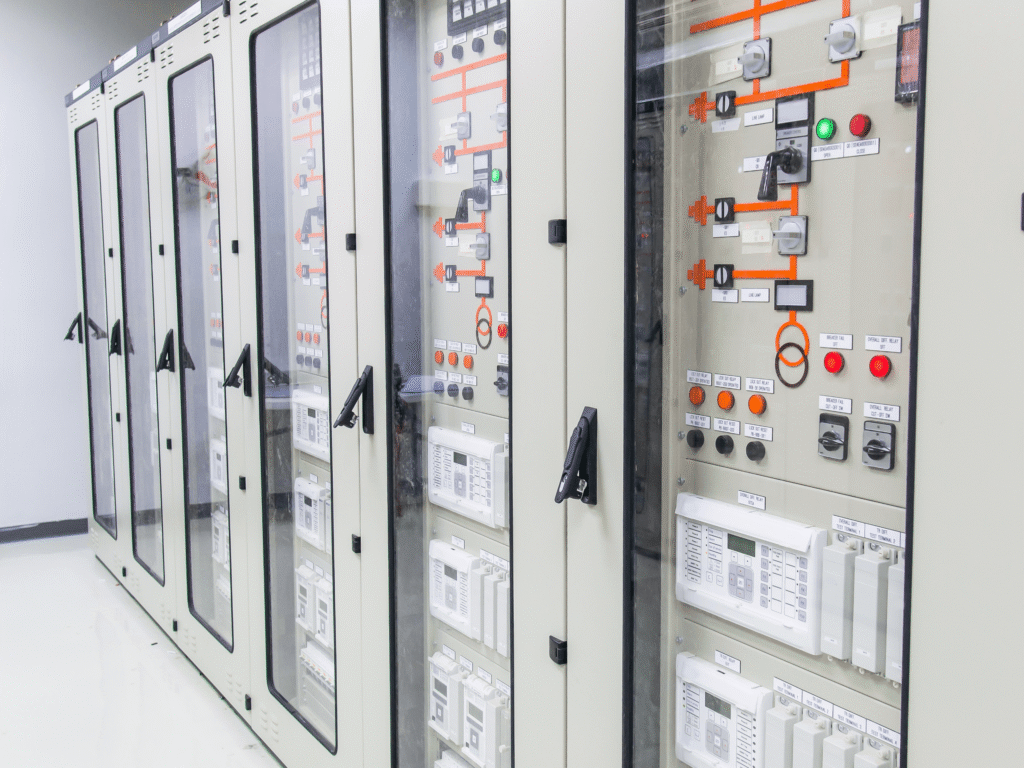

Protective Relay Panel

A Protective Relay Panel is an electrical panel designed to detect abnormal operating conditions in power systems and initiate corrective actions to prevent equipment damage. It houses protective relays, meters, annunciators, trip circuits, and communication devices. These relays monitor parameters such as current, voltage, frequency, and temperature, and automatically trip circuit breakers during faults like overloads, short circuits, earth faults, or under/over-voltage conditions. Protective relay panels enhance system safety, reliability, and continuity of power supply, and are widely used in substations, power plants, and industrial electrical networks.

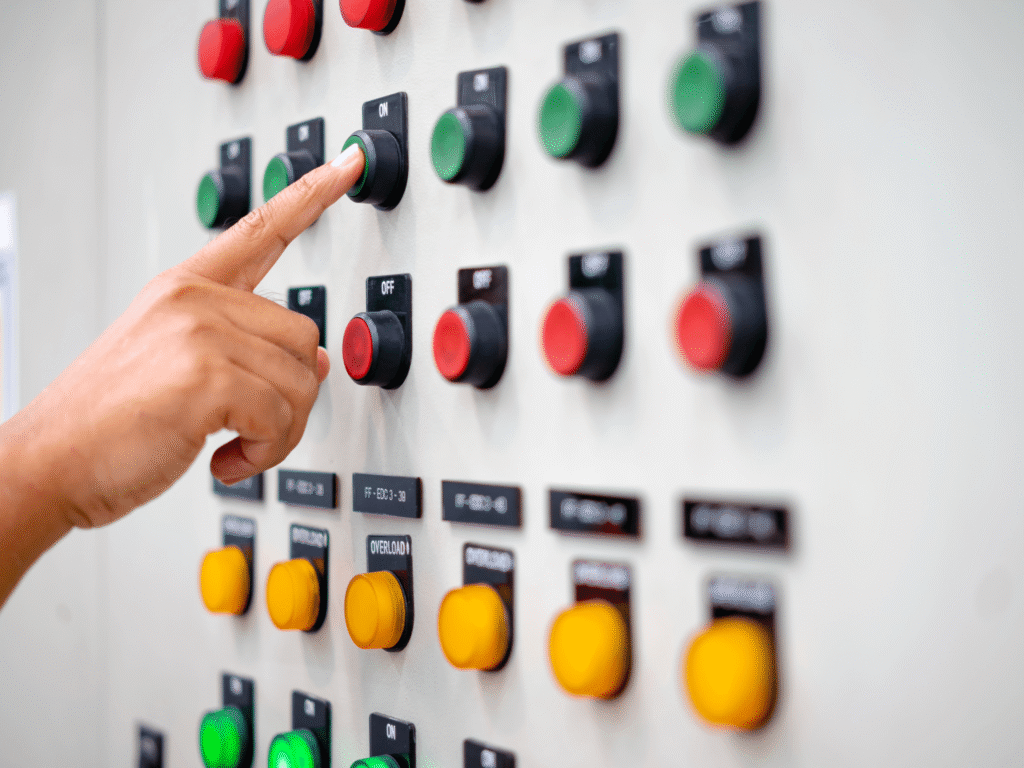

Push Button Station

A Push Button Station is a control device used to operate machines or electrical equipment manually. It consists of push buttons such as start, stop, emergency stop, and selector switches housed in an enclosure. Push button stations send control signals to panels or controllers, allowing safe and convenient operation. They are widely used in industrial automation, machinery control, conveyors, cranes, and manufacturing systems to ensure simple, reliable, and operator-friendly control.

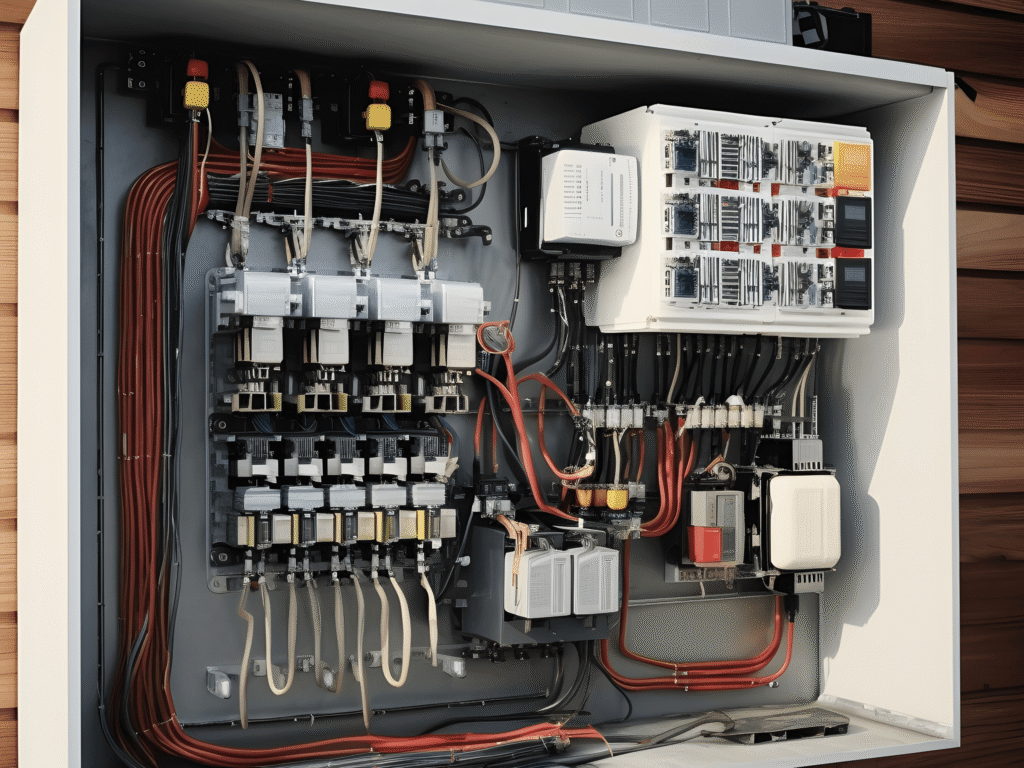

Junction Box

A Junction Box is an electrical enclosure used to safely house and protect wire connections and cable joints. It allows multiple electrical cables to be connected, branched, or terminated securely. Junction boxes prevent accidental contact, protect connections from dust, moisture, and damage, and help organize wiring. They are commonly used in residential, commercial, and industrial electrical installations to ensure safety, reliability, and ease of maintenance.

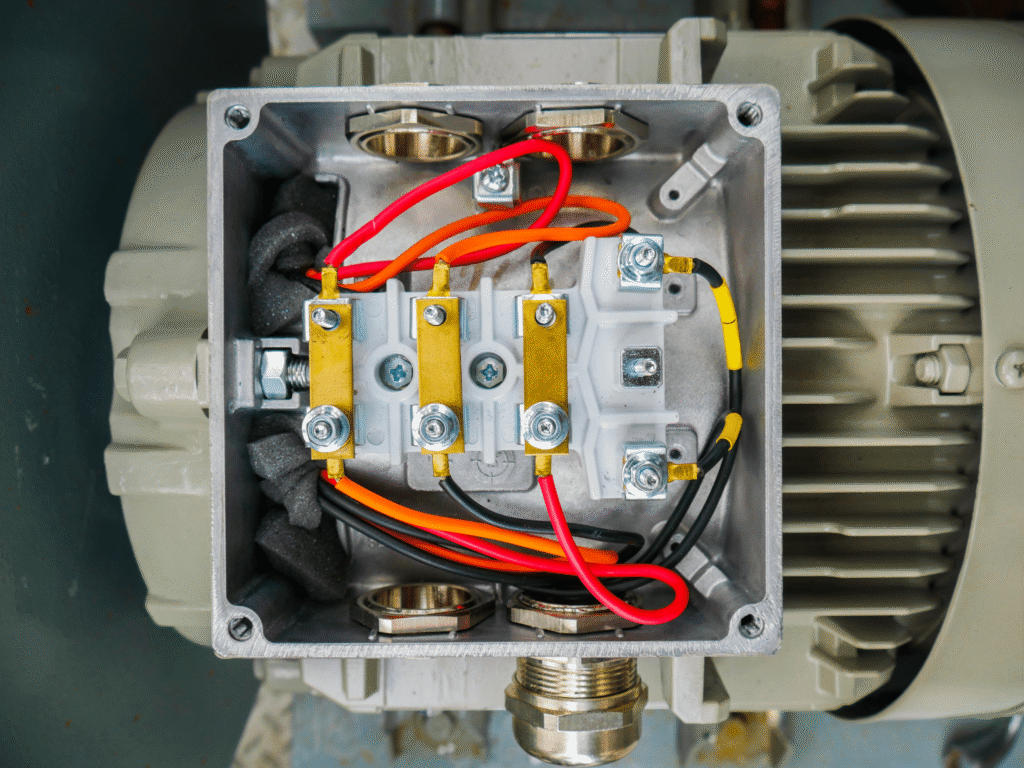

Terminal Box

A Terminal Box is an electrical enclosure used to terminate and connect electrical cables to equipment or circuits using terminal blocks. It provides a safe, organized point for wiring connections, ensuring proper insulation and strain relief. Terminal boxes protect terminals from dust, moisture, and mechanical damage, improve wiring clarity, and simplify inspection and maintenance. They are commonly used in motors, instruments, control panels, and industrial electrical systems.

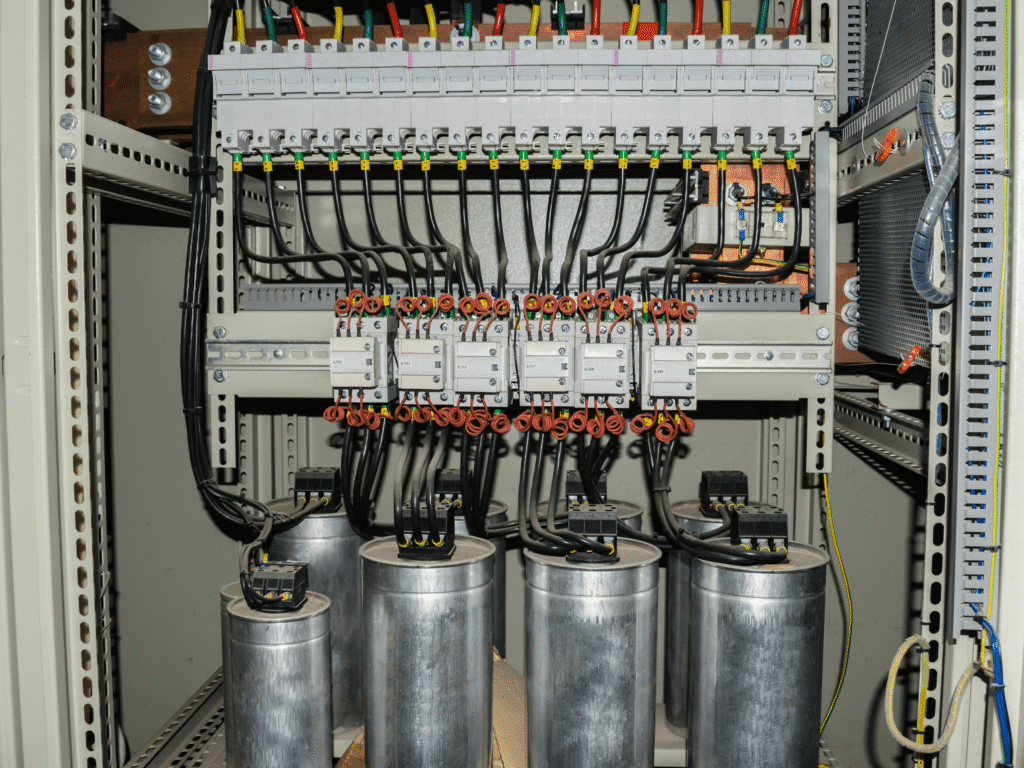

Capacitor Panel

A Capacitor Panel is an electrical panel used for power factor improvement in electrical systems. It contains capacitor banks, contactors or thyristor switches, protection devices, and an automatic power factor controller. The panel supplies reactive power to compensate for inductive loads, reducing power losses and demand charges. Capacitor panels improve voltage stability, enhance system efficiency, increase available capacity, and help avoid utility penalties. They are widely used in industrial plants, commercial buildings, and electrical distribution networks.

Power Factor Correction Panel

A Power Factor Correction (PFC) Panel is an electrical panel designed to improve and maintain the power factor of an electrical system. It uses capacitor banks, reactors, contactors or thyristor switches, and an automatic power factor controller to compensate reactive power caused by inductive loads. PFC panels reduce energy losses, improve voltage regulation, increase system efficiency, and lower electricity bills by avoiding power factor penalties. They are widely used in industrial, commercial, and utility electrical installations.

Thyristor Drive Panel

A Thyristor Drive Panel is an electrical control panel used to regulate power supplied to motors or heating loads using thyristors (SCRs). It controls output voltage and current by phase-angle control, enabling smooth speed or power regulation. The panel includes SCR modules, firing circuits, protection devices, and control interfaces. Thyristor drive panels provide precise control, high efficiency, fast response, and reliable operation, and are widely used in DC drives, furnace heating, soft starting, and heavy industrial applications.

DC Control Panel

A DC Control Panel is an electrical panel used to control, distribute, and protect direct current (DC) power in industrial and utility systems. It typically receives DC supply from batteries or rectifiers and distributes it to control circuits, protection relays, switchgear, and automation equipment. The panel includes DC MCBs, fuses, meters, alarms, and monitoring devices. DC control panels ensure reliable operation of critical systems during power failures, provide stable control power, and are widely used in substations, power plants, and industrial facilities.

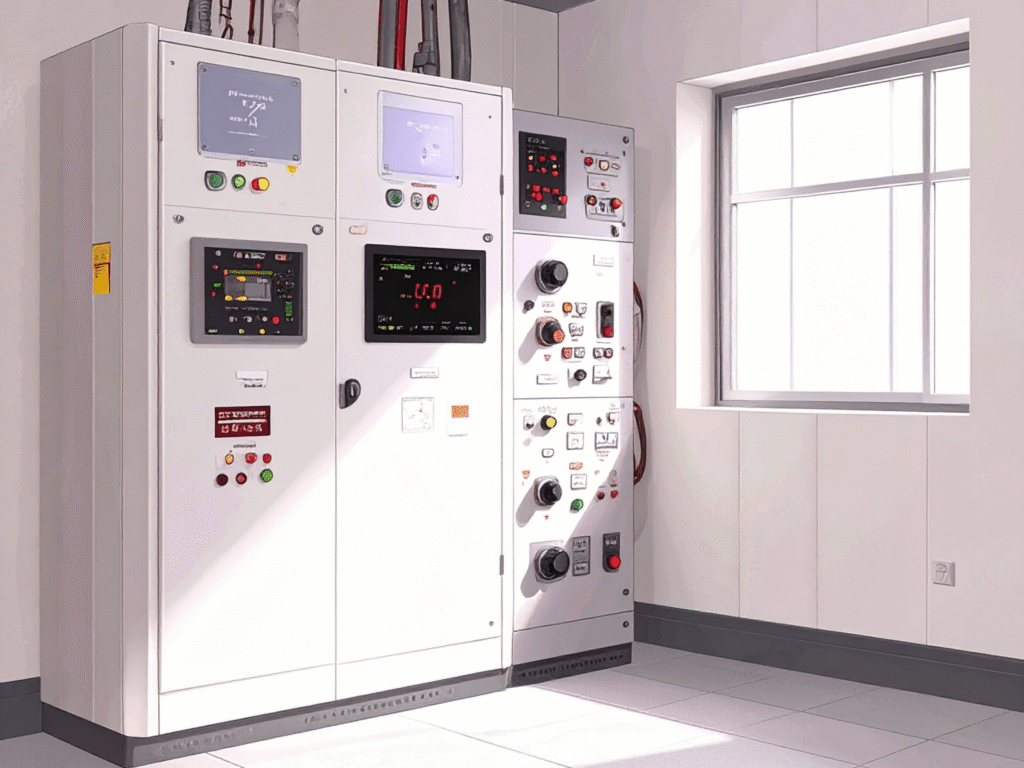

AMF Panel

An AMF Panel (Automatic Mains Failure Panel) is an electrical control panel used with diesel generator (DG) sets to automatically manage power supply. It continuously monitors the utility mains and, upon mains failure, automatically starts the generator and transfers the load to it. When mains power is restored, the panel switches the load back and safely stops the generator. AMF panels ensure uninterrupted power supply, protect equipment, and enable reliable automatic operation in commercial, industrial, and residential applications.

DG Panel

A DG Panel (Diesel Generator Panel) is an electrical control and distribution panel used to control, protect, and monitor a diesel generator set. It manages generator start/stop operations, load sharing, voltage and frequency regulation, and fault protection. The panel houses breakers, relays, meters, controllers, and safety devices. DG panels ensure safe, stable, and efficient power generation, providing reliable backup or primary power supply in industrial, commercial, and residential applications.

Feeder Panel

A Feeder Panel is an electrical distribution panel used to receive power from a main distribution source and supply it to downstream panels, loads, or equipment through feeder circuits. It contains circuit breakers, busbars, protection devices, and metering for safe power distribution. Feeder panels protect circuits from overloads, short circuits, and faults, ensure reliable power flow, and simplify isolation and maintenance. They are commonly used in industrial plants, commercial buildings, substations, and large electrical distribution systems.

Scanner Panel

A Scanner Panel is an electrical control panel used to sequentially monitor and display signals from multiple field instruments or sensors. It scans inputs such as temperature, pressure, flow, or level one by one and displays them on a common indicator or recorder. Scanner panels reduce the need for multiple displays, simplify monitoring, and help operators track process conditions efficiently. They are commonly used in process industries, control rooms, and instrumentation systems for centralized monitoring and fault detection.

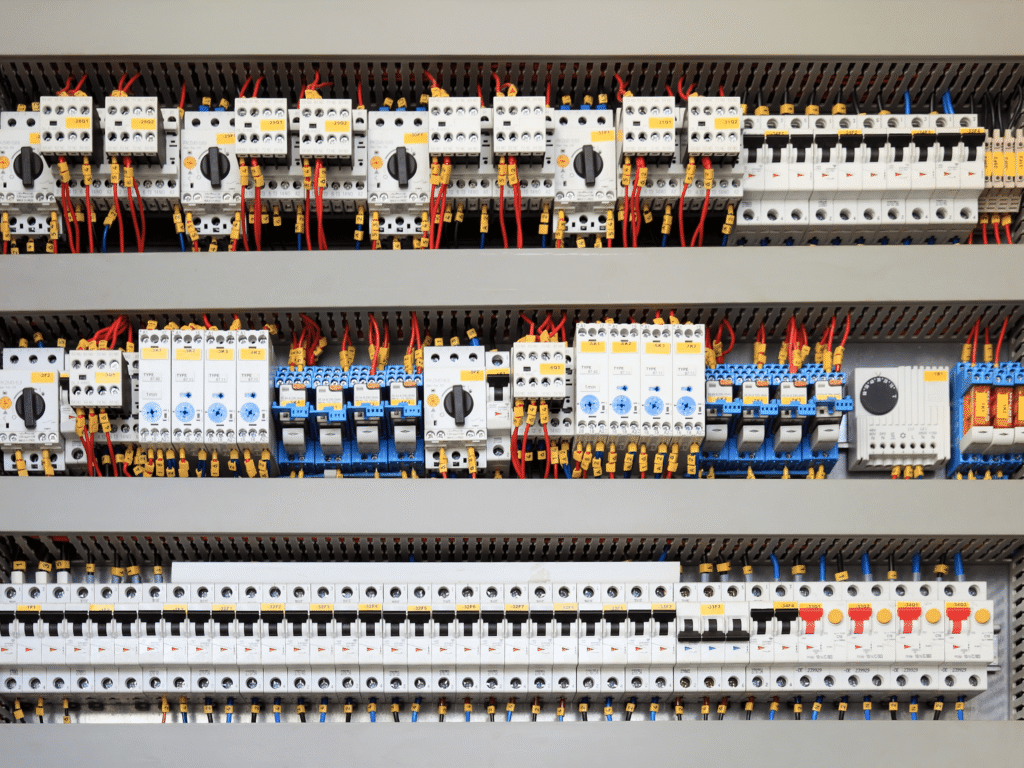

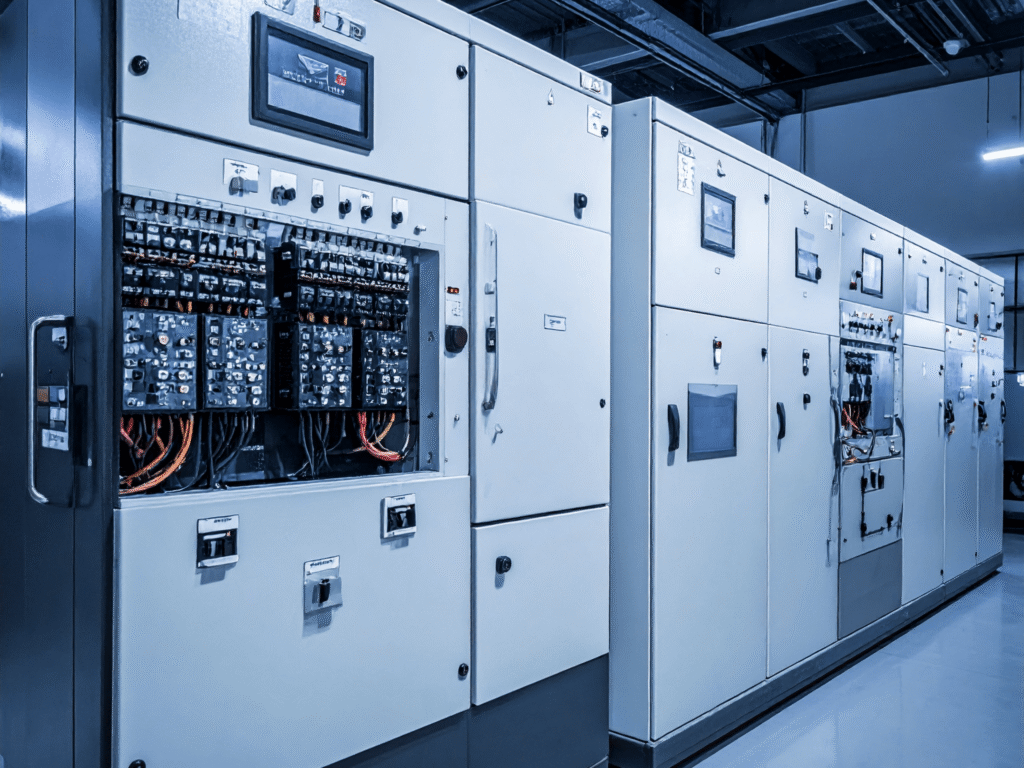

AnyType of LT Panel

An LT Panel (Low Tension Panel) is an electrical distribution panel used to receive, control, and distribute low-voltage power (up to 1000 V AC) from transformers or generators to various loads. It houses components such as ACBs, MCCBs, busbars, contactors, protection relays, and metering devices. LT panels ensure safe power distribution, protect against overloads and short circuits, improve system reliability, and simplify operation and maintenance. They are widely used in industrial plants, commercial buildings, and infrastructure projects.

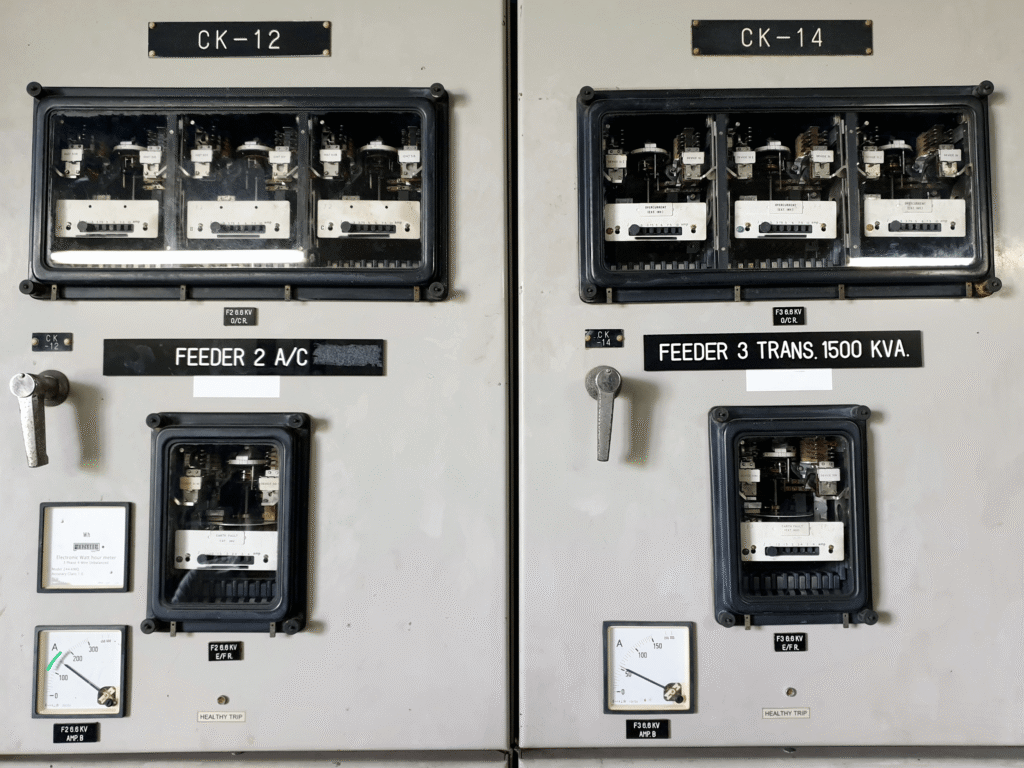

HT Relay and Control Panel

An HT Control Panel (High Tension Control Panel) is an electrical panel used to control, protect, and monitor high-voltage power systems, typically operating above 1 kV. It manages incoming and outgoing HT feeders from transformers or utility supplies. The panel includes circuit breakers (VCB/SF6), protective relays, CTs, PTs, isolators, and metering devices. HT control panels ensure safe switching, fault isolation, and reliable power distribution. They are commonly used in substations, power plants, large industrial facilities, and infrastructure projects.

Synchronizing Panel for DG Set

A Synchronizing Panel for a DG Set is an electrical control panel used to operate two or more diesel generators in parallel with each other or with the utility grid. It synchronizes generators by matching voltage, frequency, and phase sequence before connecting them. The panel enables load sharing, improves power reliability, and allows optimal generator operation. It includes synchronizing relays, controllers, breakers, meters, and protection devices. Synchronizing panels ensure safe parallel operation, prevent electrical disturbances, and are widely used in industries, hospitals, data centers, and large commercial facilities.

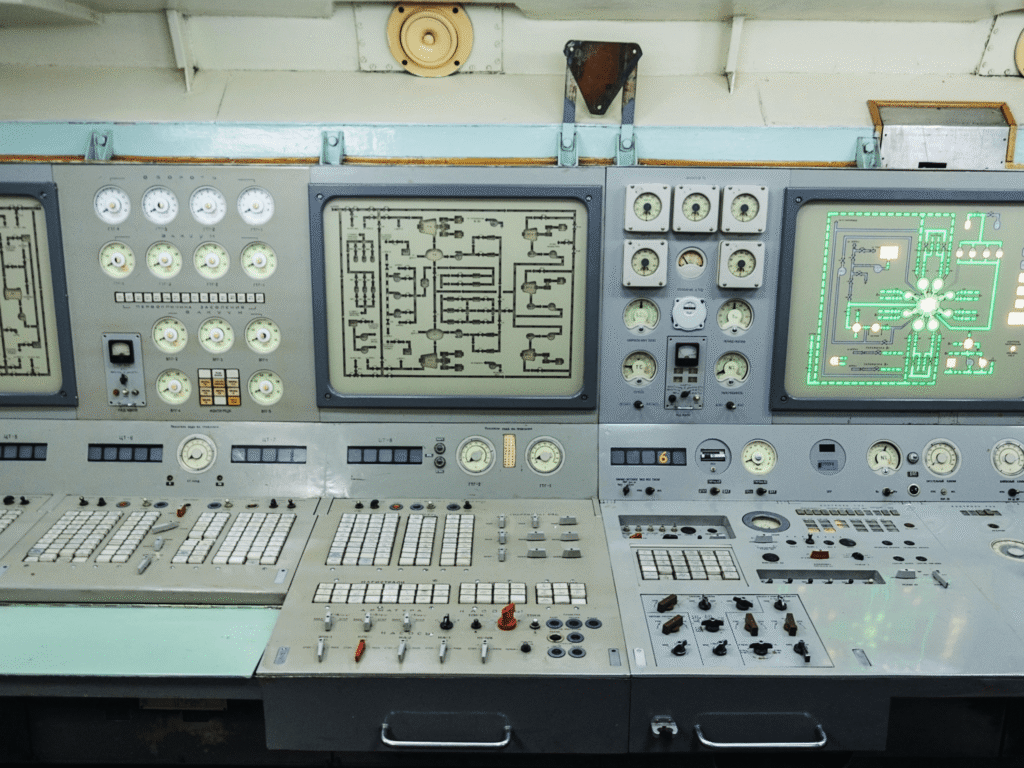

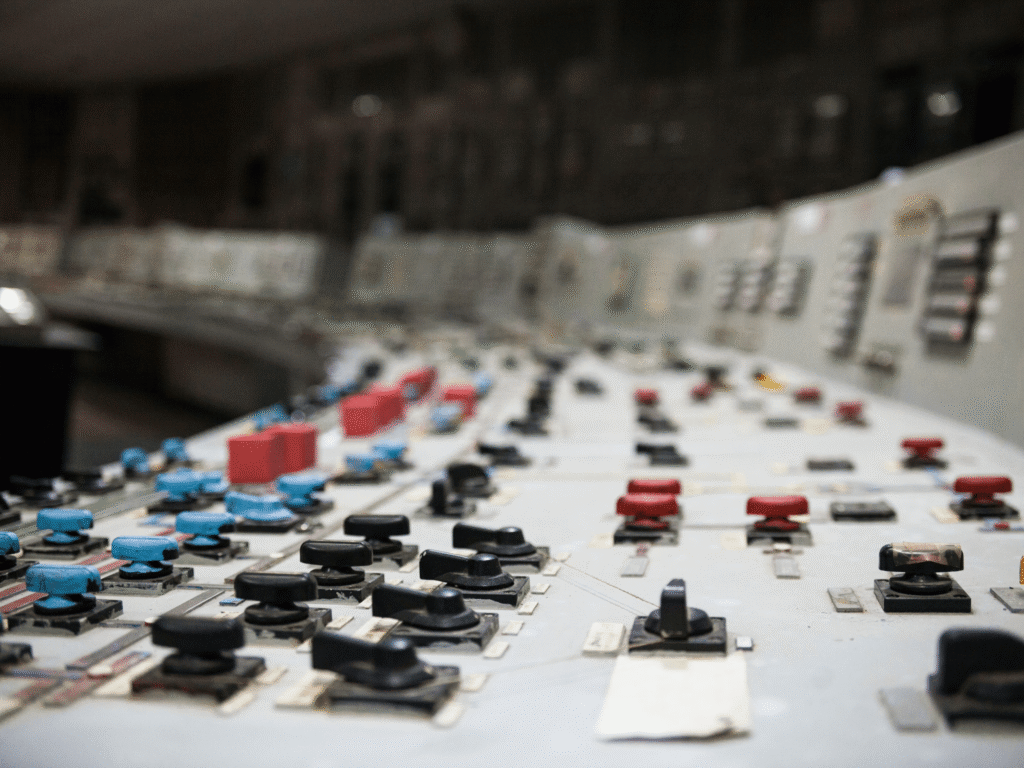

Control Desk

A Control Desk is a centralized operating station used to monitor and control industrial processes, machines, or power systems. It houses control switches, push buttons, indicators, meters, HMIs, and alarms arranged ergonomically for operator convenience. Control desks provide a clear overview of operations, enable quick decision-making, improve safety, and enhance efficiency. They are commonly used in control rooms, power plants, manufacturing units, process industries, and large automation systems.

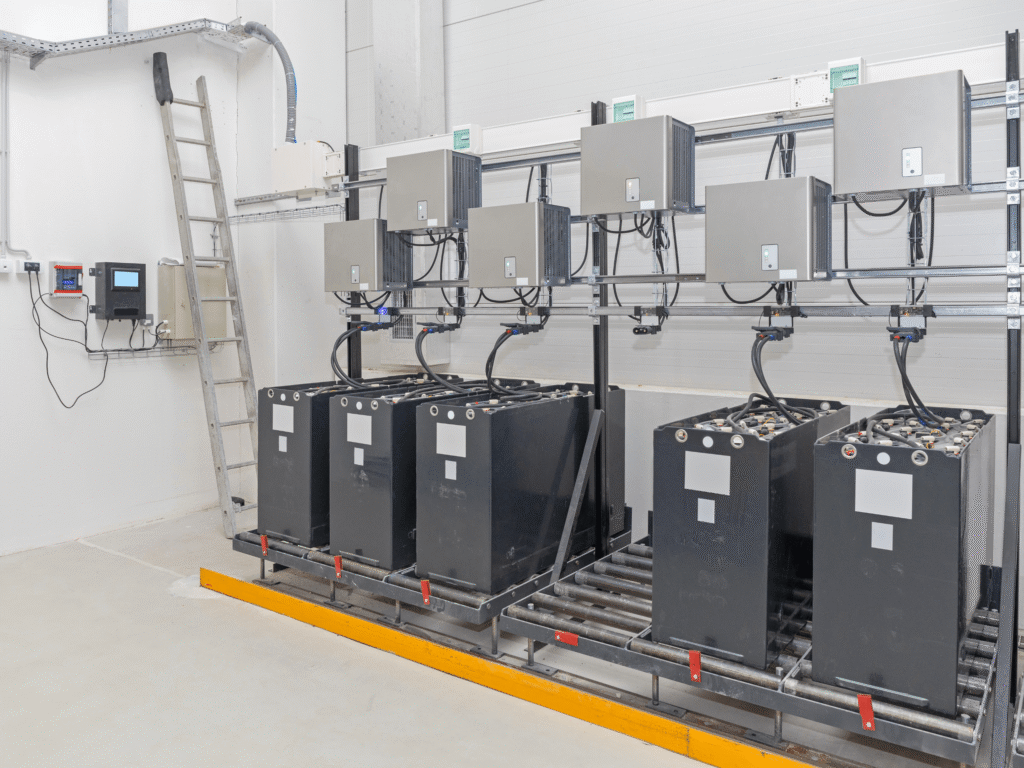

Industrial Battery Charger

An Industrial Battery Charger is a power equipment used to charge and maintain batteries that supply DC power for critical systems. It converts AC input into regulated DC output to ensure proper charging. Industrial battery chargers provide reliable backup power, support float and boost charging modes, protect batteries from overcharging, and ensure uninterrupted operation of control, protection, and emergency systems. They are widely used in substations, power plants, telecom, railways, and industrial facilities.

Bus Duct

A Bus Duct (Busway) is a prefabricated electrical distribution system consisting of enclosed bus bars housed in a metal casing. It is used to transmit and distribute large amounts of electrical power efficiently over short to medium distances. Bus ducts offer high current capacity, reduced power losses, compact installation, and easy tap-off connections. They are commonly used in industrial plants, commercial buildings, data centers, and power distribution systems as an alternative to traditional cable-based distribution.

Feeder Pillar

A Feeder Pillar is an outdoor electrical distribution enclosure used to control and distribute low-voltage power to multiple outgoing feeders. It receives power from a transformer or main distribution source and supplies it to street lighting, residential areas, or industrial loads. Feeder pillars house switches, fuses, MCBs, MCCBs, and metering equipment, providing protection against overloads and short circuits. They are weatherproof, robust, and commonly used in urban infrastructure, utilities, and industrial campuses.

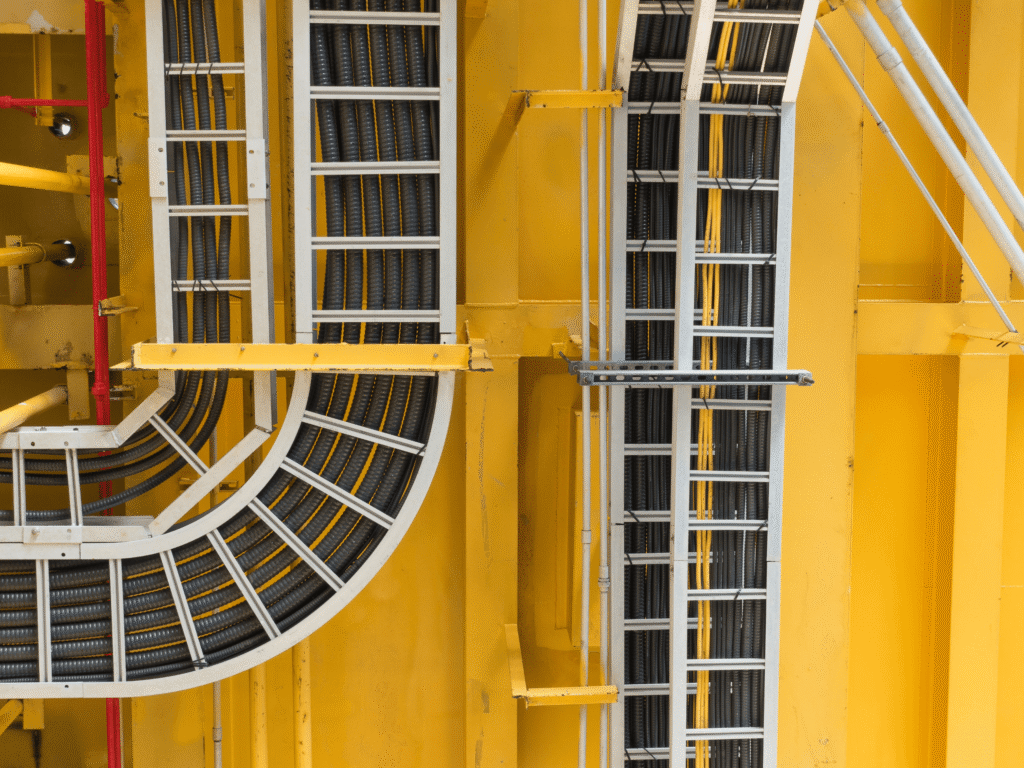

Cable Tray

A Cable Tray is a structural support system used to carry, organize, and protect electrical and communication cables. It provides a safe pathway for power, control, and data cables while allowing ventilation, easy inspection, and future expansion. Cable trays improve cable management, reduce installation time, and enhance safety. They are widely used in industrial plants, commercial buildings, data centers, and infrastructure projects as an alternative to conduit systems.

Erection, Testing & Commissioning of Electrical Equipment up to 33 kV

It involves the complete installation and safe energization of electrical systems. Erection includes positioning of panels, transformers, switchgear, and structured cable laying with proper supports. Cable termination and jointing are carried out using approved kits to ensure insulation integrity. Testing covers insulation resistance, continuity, earth resistance, high-voltage and functional tests to verify system reliability. Commissioning ensures correct operation under load, compliance with standards, and safety before handover. This process guarantees efficient, safe, and trouble-free performance of electrical installations up to 33 kV.